Battery Terminals

Strip, double ring, quick lock battery terminals

With a production that today counts

around 10 million pieces/years and with the expertise acquired over several

years of development and production, MTA is known by the major OEMs for the

mechanical technology of its battery terminals.

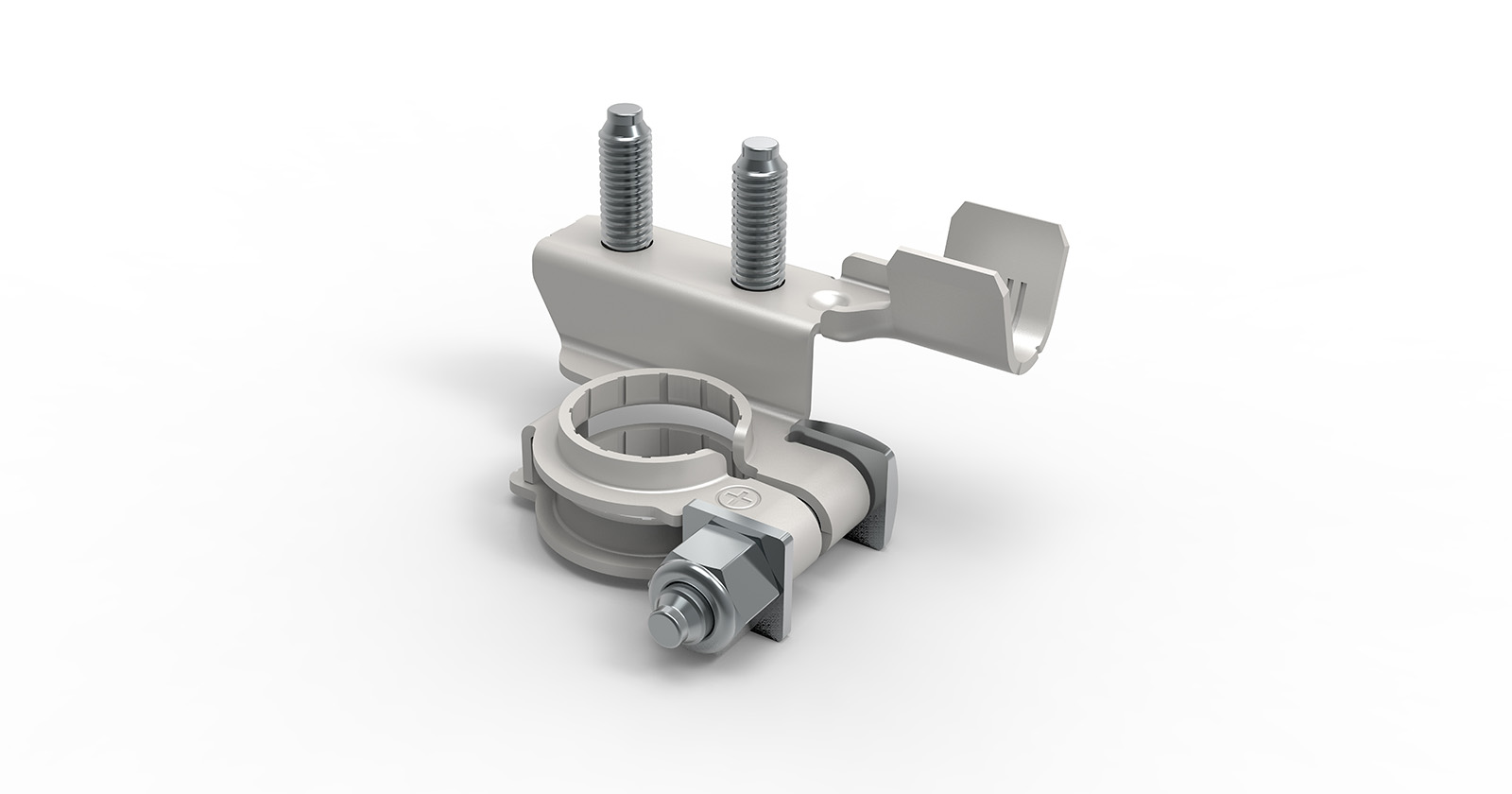

The range offers: Double ring technology

or strip type, with studs or crimping version, screw type or quick locking.

Different stamping geometries allow their

use in different layouts/configurations.

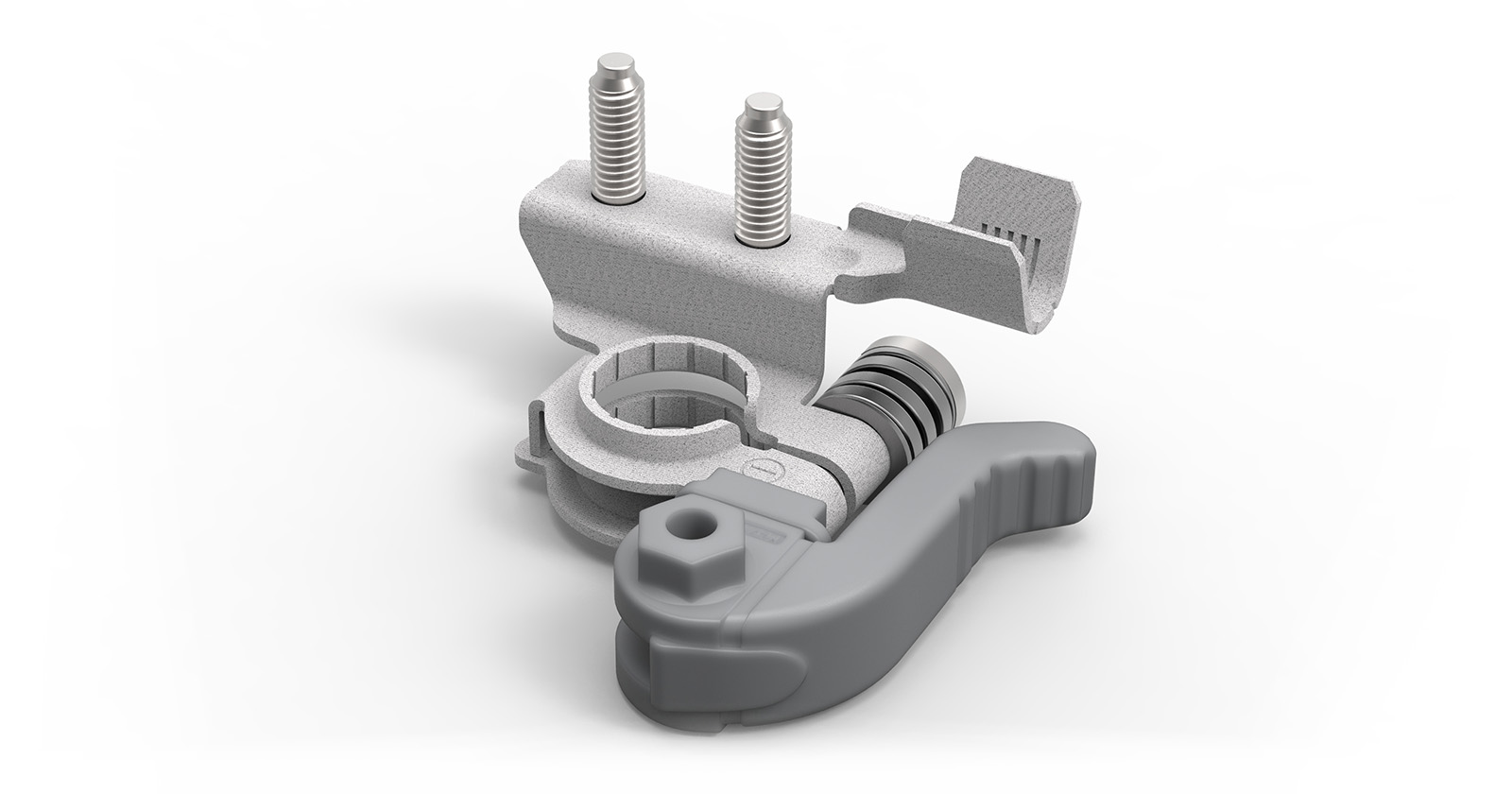

Go/No-go battery terminals

The Go/No-go battery terminal is a blank terminal for the positive and negative poles, with vertical tightening. It is distinguished by proprietary technology (developed to achieve the Go/No-go effect) that ensures correct positioning during assembly. This system inhibits tightening when the terminal has not reached the final position and is therefore not in contact with the battery surface thereby making the lock nut turn idle.

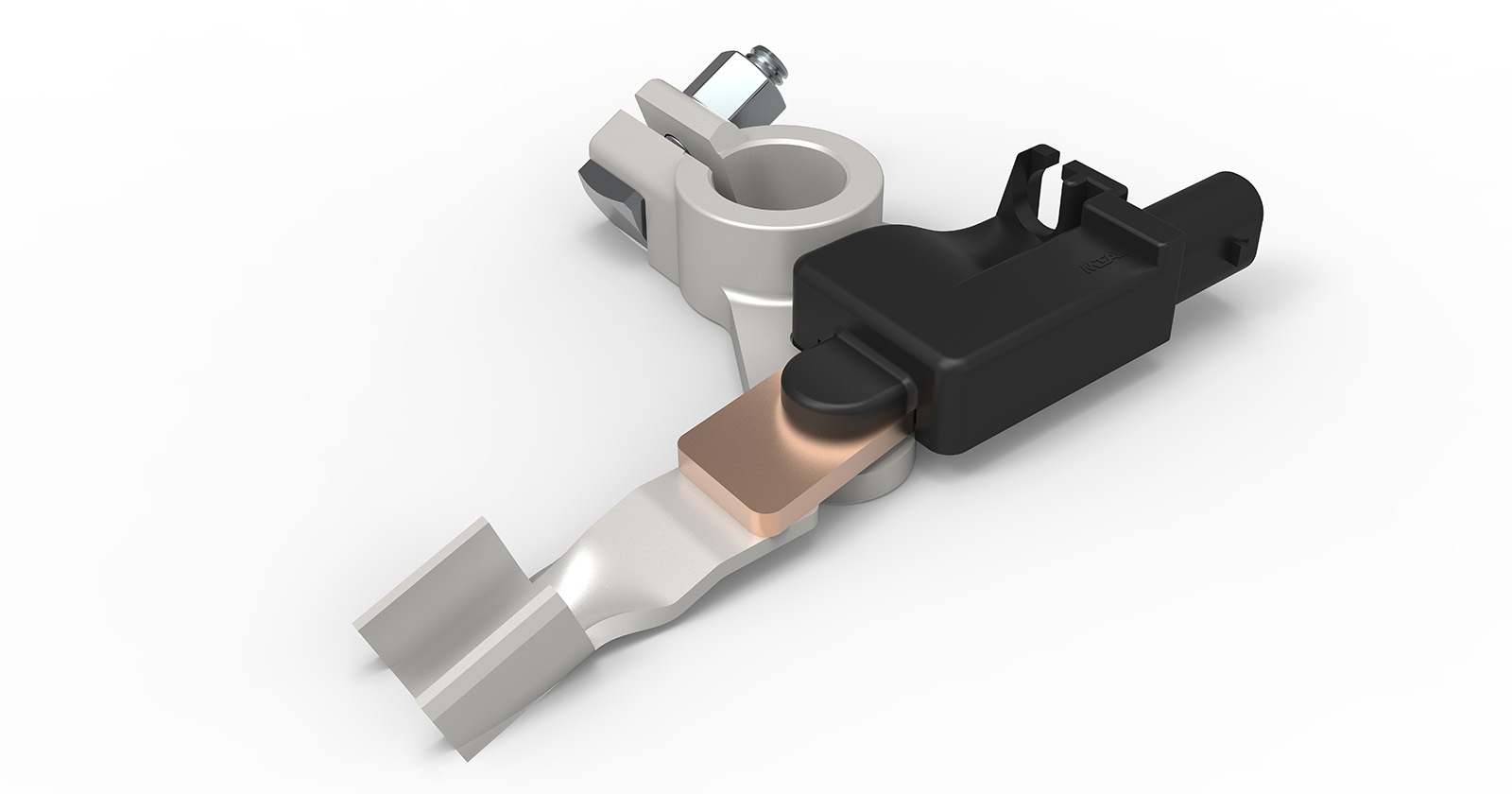

Intelligent battery terminals

The “intelligent” battery terminals with integrated sensor can measure the current, voltage and temperature of the battery and constantly monitor its state of charge, and, thanks to an algorithm with a precision of +/- 5% , they will be able to monitor the health of the battery too. This will allow the driver to be alerted when the battery is at risk, with an alert signal directly on the car's dashboard.