Brazil: production continues to expand

News – January 2023

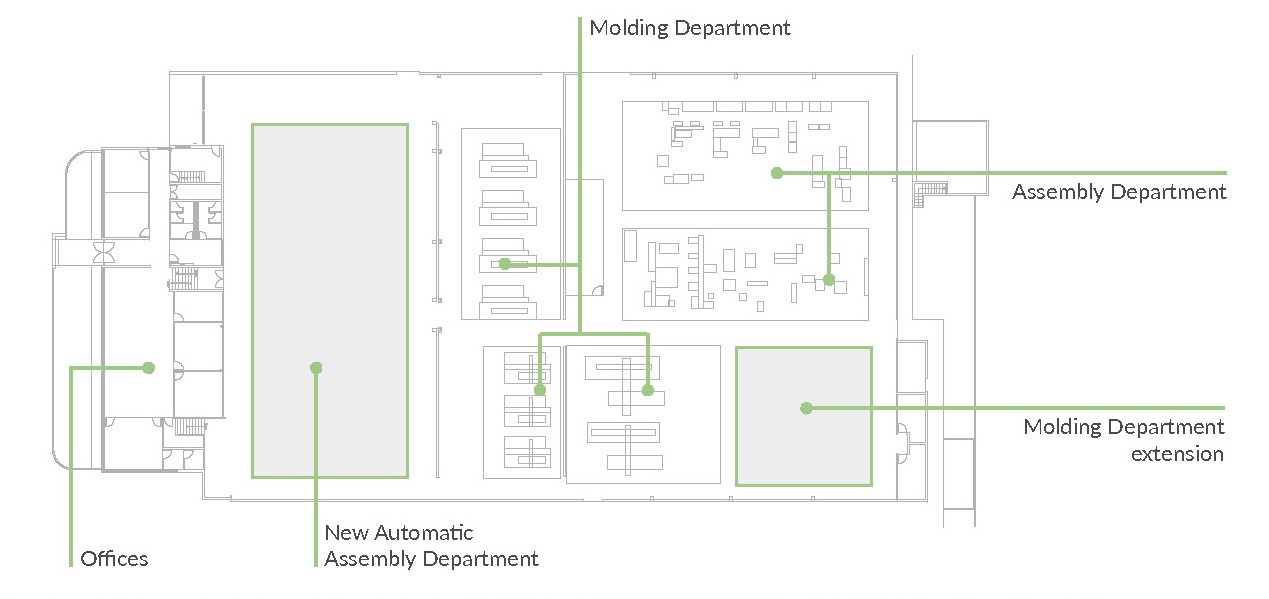

First among all the sites to be equipped with a

laboratory, which has been operational for more than ten years now, and with a

molding department with 11 presses having a tonnage ranging from 80 to 450 t,

MTA Brasil has often gone through extensions and modernizations, which have

allowed an increase in production capacity and significant growth in turnover.

We’ve told you about these developments in a

number of past issues, but recent projects acquired for some of the most

important vehicle manufacturers in the Latin American market have required even

more space for new assembly lines with a high level of automation.

The warehouse was therefore moved to another

nearby building, freeing up a significant amount of space that will be

completely devoted to these automated assembly lines.

The benefits that MTA Brasil will be able to

offer customers are clear. Increased production capacity will improve

time-to-market for Mercosur.

In fact, MTA Brasil and MTA Mexico guarantee our

strong presence in the American market also through mutual partnerships aimed

at optimizing the production of some components.

Assembly Departments

With different production sites available, MTA can manage product assembly strategically