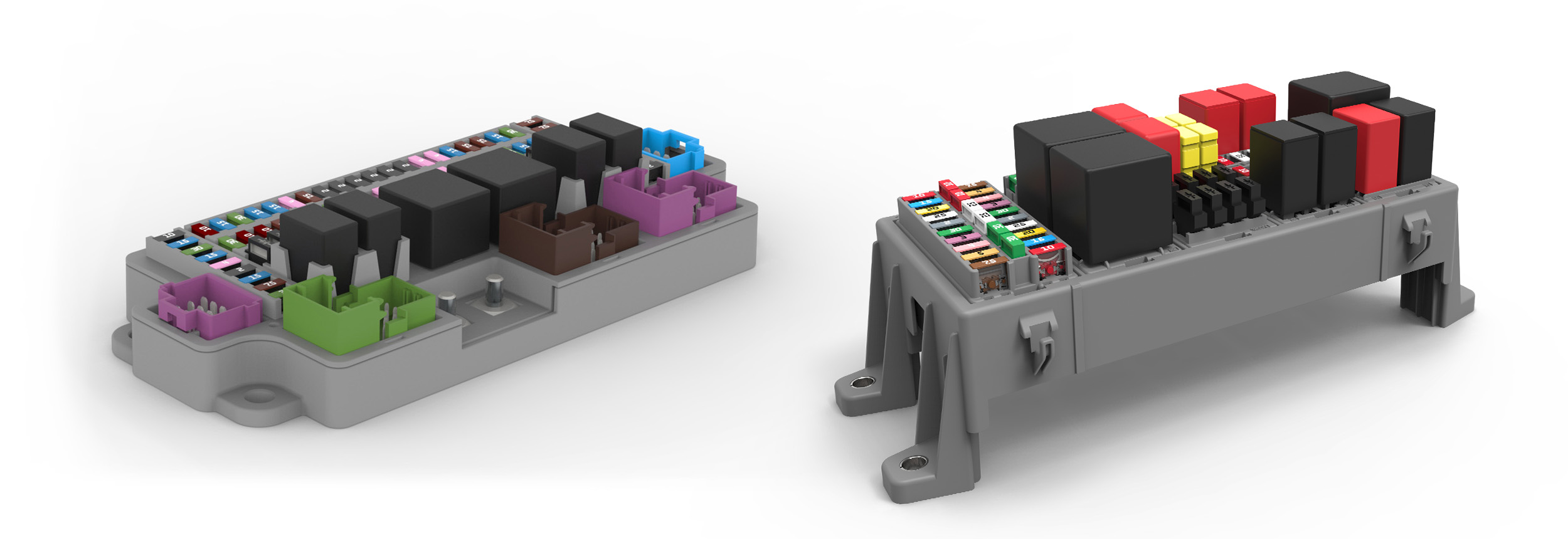

C-MEC 138

Cabin-Modular Electrical Center with PCB

MTA News – September 2019

For many years MTA has been a leading

company in the field of electrical protection for the automotive market, and in

particular for the off-highway sector. MTA has expanded its traditional range

of wired products to include the alternative with PCB, a technology that allows

it to perform the same functions as wired units with the advantage of

optimizing cables, facilitating assembly in production lines, and direct supply

to the manufacturer which can install the unit directly on the car.

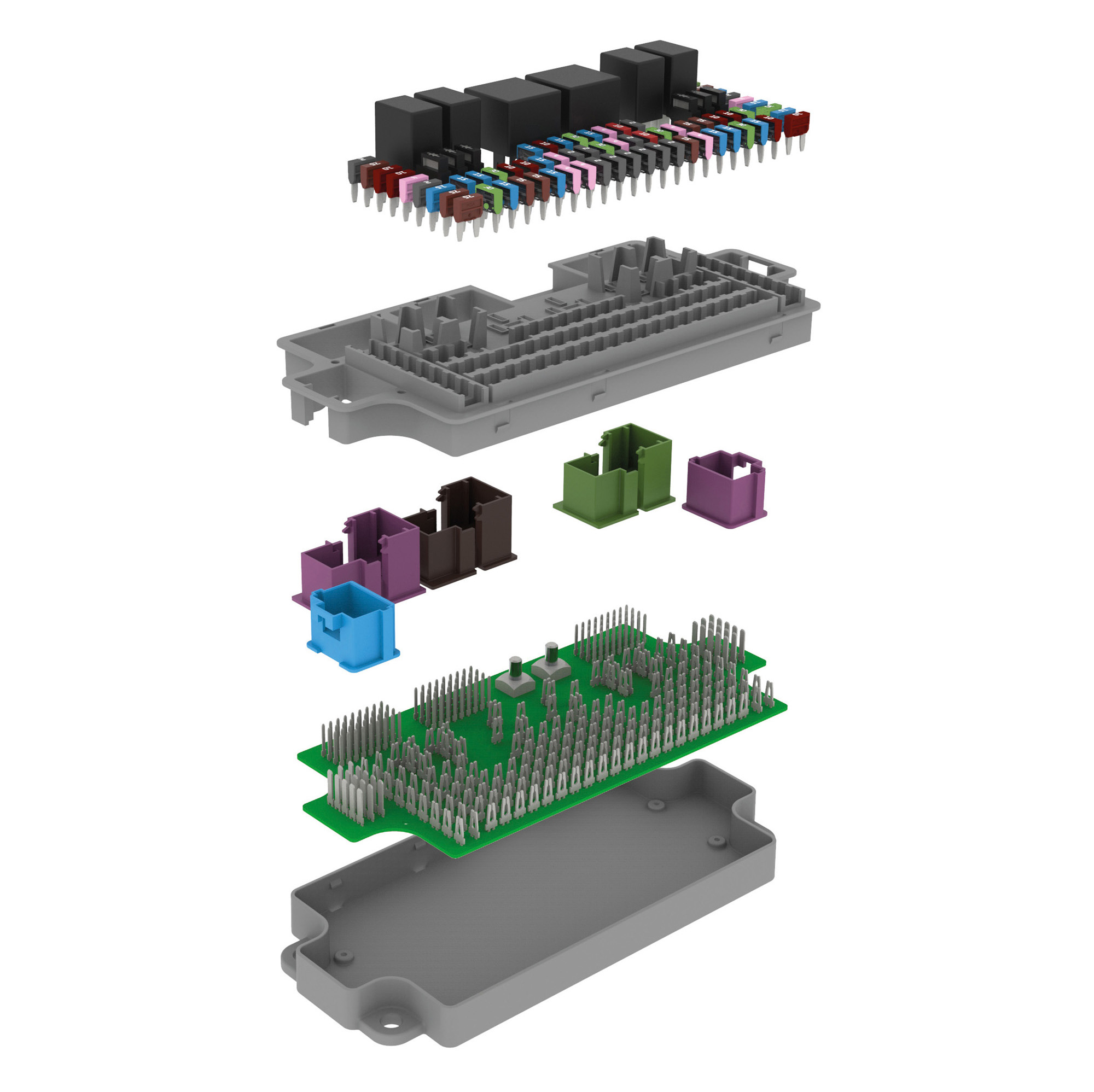

The MEC 97 unit with PCB made with

press-fit, a technology that MTA has chosen as an alternative to welding, was

designed for the engine compartment and has been available for a couple of

years now. For installation in the cabin the C-MEC 138 is now available,

designed and built with features similar to the MEC 97, i.e., with press-fit

technology and with a high level of customization.

The C-MEC 138 is ideal for new applications

and for those who already use our five-way frame, with which it is perfectly

interchangeable.

The C-MEC 138 has a rational design,

including a base that always remains the same, connectors unconnected from the

mask, and a customizable mask. Where the customer needs to change only the

fuses it will keep the mask, the connectors and the existing PCB. Where the

contents remain the same but there is a need to change the scheme, with a very

small investment and very short lead times the PCB alone will be changed. If

both the PCB and the contents do not correspond to the customer's needs, just

the PCB and the mask can be redesigned. The changing of the latter, not having

integrated connectors, will require a relatively simple mold, with reduced

costs and time.

This first cabin compartment unit with PCB will

surely be followed by others with different dimensions according to the

market's demands, maybe even developing solutions that are interchangeable with

the other MTA frames already used by customers.

- The C-MEC 138 is perfectly interchangeable with our five-way frame.

C-MEC 138 technical data sheet

Download the technical data sheet for the specifications of this electrical center.