Electric modules become “intelligent”

News – January 2023

MTA’s offer for Off-the-shelf products which can be

customised according to the specific application they are intended for, has

grown.

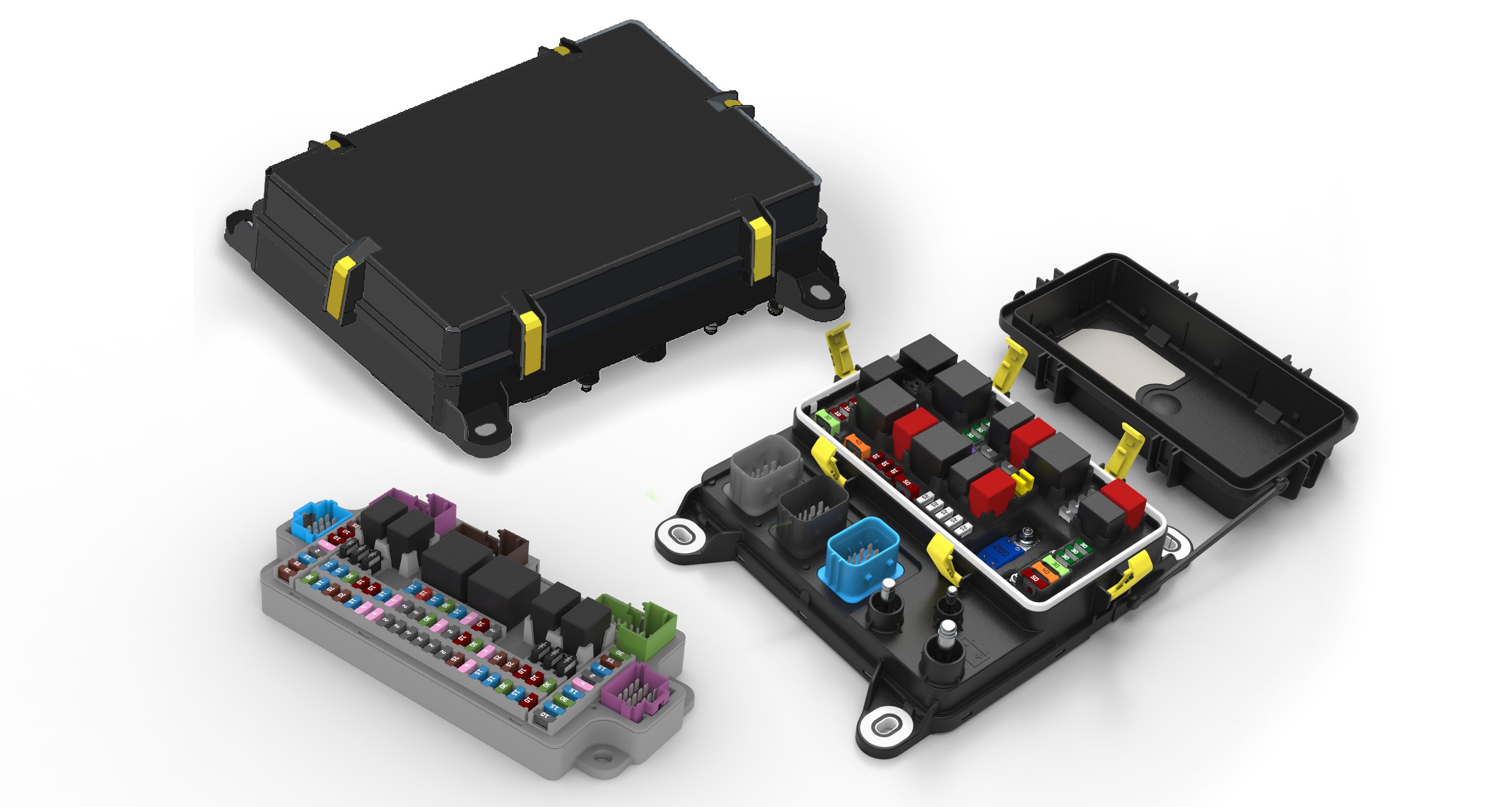

The MEC 97 and the Maxi-MEC, designed

for the engine compartment, and the C-MEC 138, for installation in the

cabin, are plug & play Modular Electric Centers with a press-fit PCB

specifically designed for agriculture and construction applications.

They have a rational design,

compact dimensions and allow to integrate all the functions in one piece, thus

eliminating the need of using different modules and associated wirings. The

vehicle is therefore lightened from costly and heavy modules and cables, the

wiring layout is simplified and the assembly time reduced.

The MECs have different customisation levels and, for

example, for different fuses/relays configuration, a simple replacement of a

mask is enough.

- MEC 97, Maxi-MEC, C-MEC 138

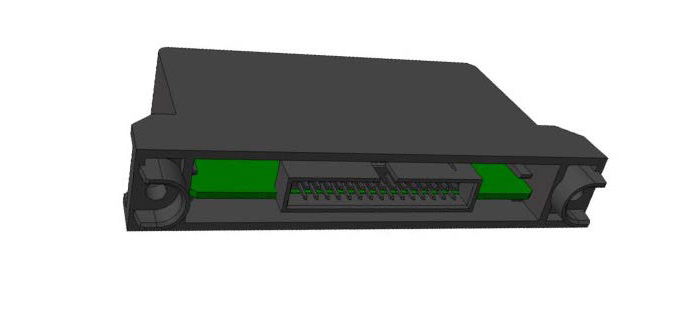

- CAN Module

Today, faced with the request of

many customers who need to use a CAN Bus line, MTA is developing a CAN Module

Plug-in, which can drive the MEC’s relays by CAN Bus, to make these products

even more performing.

This way the Modular Electric

Centers will become “Smart Modular Electric Centers”.

The CAN Module Plug-in, will

connect the Modular Electric Centers with the CAN Bus line to generate

the actuations needed.

The CAN Bus Module can be

programmed through MTA Studio, like MTA customizable dashboards, displays and

ECUs. This represents a great advantage for those already using some MTA

products, allowing to obtain the best synergies.

Off-the-shelf Power Distribution Units

Designated for heavy duty power distribution and main electric services protection, MTA PDUs are developed based on a modular design concept for the utmost versatility.