One product, multiple functions

MEC 97 makes it possible to simplify wiring and reduce assembly times

News – January 2023

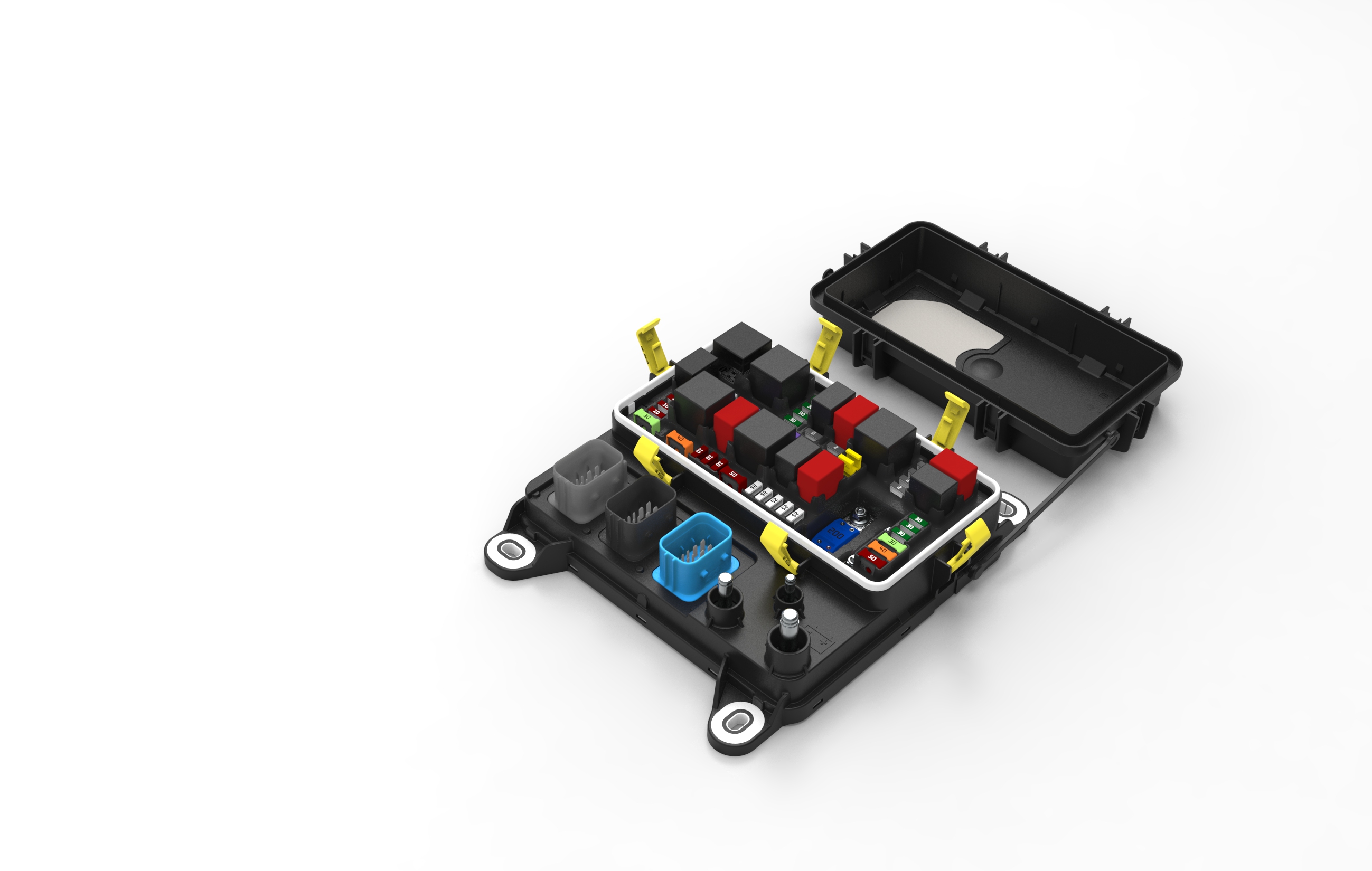

Rationalize the power distribution and

protection of the main electrical consumers in the engine compartment of some

of its off-highway vehicles: this was the goal set by CNH Industrial that led

us to develop MEC 97 in close collaboration with its engineering division. MEC

97 is a unit that is the result of the synergistic efforts of our Business

Units, which have integrated their know-how to create a compact product capable

of encompassing the functionality of the various products we used to supply.

What are the benefits? A simplification in the wiring, a tidier layout, and

reduced assembly time.

MEC 97 is a plug-and-play product, PCB-type,

whose pins are assembled by press-fitting, which ensures optimal electrical

contacts even under strong vibrations. Thanks to the PCB logic, the control

unit also proves to be very versatile: in fact, by changing only the PCB and

varying the number of connectors, the customer was able to use MEC 97 on a

variety of applications. The first was for New Holland-branded T6 and T7

tractors, then supply was extended to other CNH agricultural applications in

the EMEA market, and recently to a 4WD vehicle for the construction world in

NAFTA.

The PCB for MEC 97 is made at our Italian plant

in Rolo, from where it is then sent to MTA Slovakia where the unit is

manufactured.

- New Holland T6 Series © Copyright CNH Industrial

Off-the-shelf Power Distribution Units

Designated for heavy duty power distribution and main electric services protection, MTA PDUs are developed based on a modular design concept for the utmost versatility.