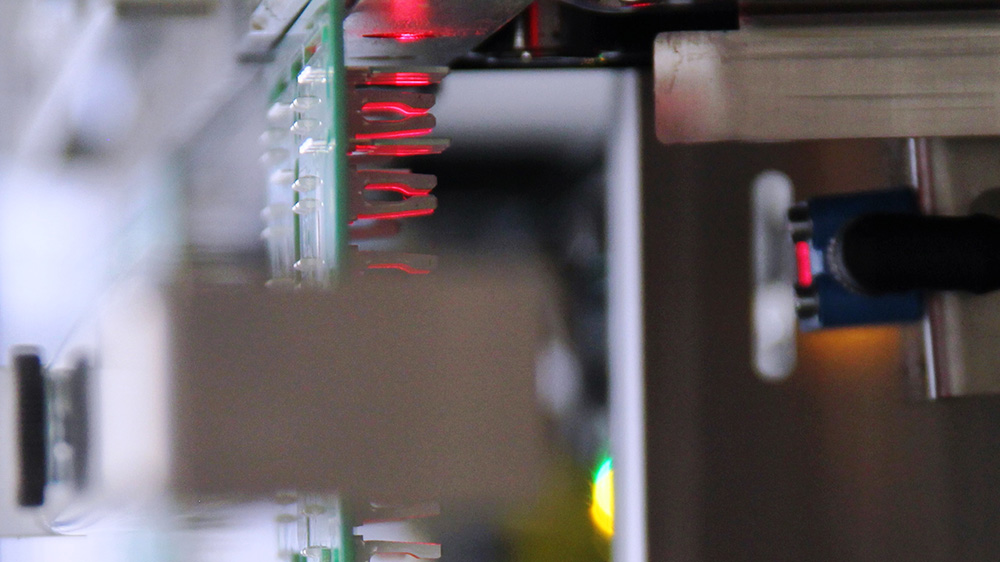

For all

new units with printed circuit boards, for many years now MTA has adopted

solderless connection technology based on press-fitting a contact into a

metalized through-hole in the PCB. This technology is characterized by good

conductivity and superior mechanical strength and will make it possible in the

future to equip all electronic boards with clean connections without the

hazards of soldering.

This technology is therefore perfect for the

printed circuit boards increasingly found in modern vehicles, which are full of

electronic systems dedicated to safety, infotainment, and driver assistance,

requiring extremely reliable electrical connections. Not to mention the fact

that they often operate in extreme temperatures, dust, humidity, and chemicals.

Today there are eight Press-Fit lines in MTA sites around the world and they are located in Italy, Slovakia, Morocco, Brazil, and China. We have two different types: one to ensure very high productivity when the numbers require it, the other more suitable for lower volumes as it allows greater flexibility, ensuring shorter setup times.

Both types have a control system for all

parameters such as:

• Adaptation

to the thickness of the printed circuit board.

• Strict

control of the force and insertion height of each individual terminal.

• 100%

optical inspection of the dimensional compliance of the terminals, and

especially the GAPs of the Forks where fuses and relays are inserted.

• Complete

data traceability of each individual inserted terminal associated with each

individual product.

→ Press-Fit lines are in Italy, Brazil,

Slovakia, China and Morocco.