New Fuses by MTA

Codogno (Italy), January 24 th 2011.

MTA has been delivering to the OE automotive sector since decades electromechanical components that represent the state of the art of technology and that are constantly renewed to meet the rapid changes of this sector.

A good example is the one of fuses, complex products that have to protect the electric system of the car. The increasing demands in terms of lightweight, compact size and low costs forbid the use of big cross-section cables inside the car. Therefore the fuses, that have to protect smaller cables, must be able to blow even faster than they did in the past.

MTA’s Minival offering

Because of these needs, MTA has renewed its range of MINIVal fuses, designed for a 5 to20 A current range. Like any other electric component, fuses must adhere to specifications provided for by reference ISO standards. ISO specifications applicable to MTA's MINIvalfuses (and similar competitor products) equire a maximum blow time of 30 minutes (i.e.1800 seconds) when tested at an input current of 135% of maximum current capacity.Unfortunately, this ISO standard dates back to a few years ago and this requirement nolonger ensures full protection for these smaller cables. MTA has demonstrated to be a forerunner once again: it has anticipated the updates to ISO requirements that are sure tocome and produces MINI fuses designed for a maximum blow time of 2 minutes (120seconds) – a notable improvement, applied current being equal – This performancepermits small cables to be used with significant savings in terms of costs, weight and volume. The shorter blow time of MINI fuses is made possible by a process MTA is very proud ofand that was accomplished in the R&D facilities of the company. Among the used techniques to achieve this challenging goal there were sophisticated statistical analysis based on the so-called Six Sigma systems to significantly improve process capability.

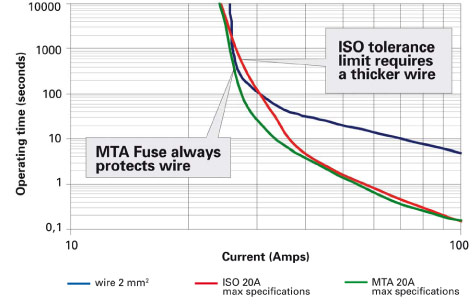

Chart 1

The chart shows a protection curve, the blue one, for a 2 sq mm cable, with the red and green lines representing a 20A fuse manufactured to current ISO specifications and a MTA 20A fuse, respectively. Full protection is ensured when a fuse's curve lies below the cable curve. Looking at the chart, it becomes apparent that protecting a cable with a fuse made to ISO specifications involves using a bigger cross-section cable, with the associated extra costs mentioned above.

MTA's MAXIVAL offering – a new product

The starting point for the development of these products was the same. Traditional MAXI fuses could not ensure full protection for the “modern” bigger cross-section cables mentioned above in the event of overcurrents, because they were too slow to blow. Once again, MTA is offering a product – the MAXI Compact fuse – designed for a 20 to 60 A current range, developed from scratch and that can ensure full protection for small cables, currents involved being equal. At the same time, MTA made the MAXI Compact smaller than the traditional MAXI and competitor products for equivalent applications, so as to meet the requirements of the automotive industry. With respect to the traditional MAXI offering, for which ISO specifications require a maximum blow time of 30 minutes (i.e. 1800 seconds) when tested at an input current of 135% of maximum current capacity, the Compact fuses have a really very low maximum blow time of only 300 seconds. This MTA managed by working on the thicknesses of the materials involved – "smaller and thicker" is the underlying philosophy – based on an analysis of the melting behavior of the fuse blade. Again with the use of curve of the fuse was affected by blade geometry and selected special, but very effective shapes. All this was achieved while avoiding any increase in contact area temperature. What MTA managed to do is basically concentrate heat within the blow area, preventing its transfer to the terminals. The new “Compact” fuses have already undergone extensive laboratory testing and the first lots are ready for the customers.

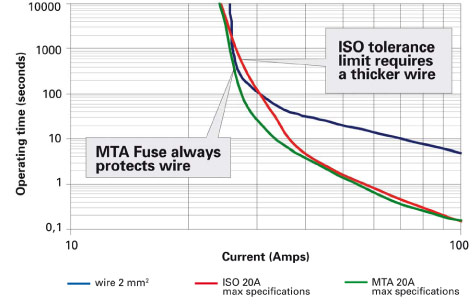

Chart 2

The chart shows a protection curve, the blue one, for a 6 sq mm cable, with the red and green lines representing a 40A fuse manufactured to current ISO specifications and a MTA 40A fuse, respectively.